To treat

posterior segment eye diseases, four routes are available i.e., topical,

periocular, intraocular and systemic. Topical and systemic routes are not

preferred route of drug administration because of having some significant disadvantages

i.e., low ocular bioavailability of drug, frequent administration of high

amount of drugs1.

Periocular route is the most preferable

route for instillation of drug to the posterior segment of eye2

ensuring higher retinal and vitreal drug bioavailability (0.01-0.1%) which is

higher than topical medication

(≤ 0.001%)3. Sub-tenon route is most preferable periocular

route. The disadvantages of this route include cataract, hyphema, corneal

decompensation and rise in intra ocular pressure. Disadvantages of intravitreal

steroid injections are worse than periocular sub-tenon pathway. Therefore,

sub-tenon route is preferred pathway for administration of steroid4.

Intravitreal injections have earned fame

among researchers and clinicians. Unlike topical and systemic routes, it offers

high concentration of drug to vitreous, retina and choroid5. Though

it ensures bioavailability of drug, instillation of drug through this pathway

is invasive and potentially risky which causes endophthalmitis, retinal

detachment and vitreous hemorrhages6.

Scientists have made many efforts to

enhance bioavailability of drug by designing different drug delivery systems

i.e. ointments, suspensions, gels, collagen shields, implants and hydrogels7.

In general there are three types of implants available in market for treatment

of posterior segment eye diseases: non-biodegradable, biodegradable and stimuli

responsive implants. In non-biodegradable implants, FDA has approved Vitrasert®

and Retisert®. Former implant carries ganciclovir drug for treatment

of Cytomegalo virus retinitis. It releases drug for 8 months. While the later

implant carries fluocinolone acetonide to treat chronic non-infectious

posterior uveitis. Iluvien® implant is waiting for FDA approval but

accepted in some EU countries. For degradable implants, FDA has approved only

Ozurdex®. None of these implants are available in Pakistan for

treatment of patients suffering from posterior segment eye diseases. However, each system has its own advantages

and disadvantages.8

Among all such devices, in-situ forming hydrogel

has gained enormous attention by scientists. These hydrogels are liquid at room

temperature and solid under physiological conditions9. These in-situ

hydrogels can be achieved by several ways such as pH change, ionic cross

linkage and temperature modulation. Among all these, thermosensitive hydrogels

got immense attention for ocular treatments because of its easy handling and

low viscosity at room temperature10,11.

Chitosan,

(poly-β(1,4)-d-glucosamine),

has been extensively used as implant in the form of gels, fibers and membranes

in the field of tissue engineering and biomedical sciences and drug controlled

release systems. Since chitosan is highly biocompatible, therefore, it has been

extensively used for the synthesis of thermosensitive hydrogels which help to

treat ocular diseases. Various drugs have been loaded on to chitosan based

thermosensitive hydrogels for treatment of ocular diseases for example, latanoprost

was loaded on chitosan and gelatin based thermosensitive hydrogel for

controlling ocular hypertension12. Chitosan in combination

with disodium α-d-glucose 1-phosphate (DGP) has been used for ocular drug

delivery system13. A novel copolymer, poly (N-isopropylacrylamide)–chitosan

(PNIPAAm–CS), was investigated for its thermosensitive in situ gel-forming

properties and potential utilization for ocular drug delivery14.

Another novel thermosensitive hydrogel was made by using chitosan and

glycidyltrimethylammonium chloride (GTMAC) and named as N-[(2-hydroxy-3-trimethylammonium)

propyl] chitosan chloride (HTCC)15.

Chitosan has been used

as a carrier of dexamethasone drug to treat ocular diseases i.e., Mucoadhesive chitosan-coated cationic microemulsion of

dexamethasone for ocular delivery16,18. Keeping in mind all such

information, in present work, we are for the first time, aiming to use

biodegradable chitosan thermosensitive gel loaded with dexamethasone and

finding the potential use of sub-tenon space for insertion of these synthesized

gels. This will provide sustained release of drug and will overcome the side

effects of previous treatments to treat posterior segment eye diseases especially

macular edema and uveitis. The cost of pre-existing treatments of these

diseases are expensive and sometimes unaffordable when considering needs of

individual patient.

MATERIAL AND METHODS

Chitosan (DD = 80.91% and Mol. Wt. =

25992.88) was synthesized in our laboratories. Acetic acid (CH3COOH)

was purchased from Riedel-deHaen (origin). From Bio world (origin) PBS

(Phosphate Buffer Saline) was bought. NaHCO3 was bought from Daejung

chemicals and metals CO., LTD (Korea). Dexamethasone was bought from Zhejiang

Xianju Junye pharmaceutical Co., Ltd (China). NaCl was obtained from Omicron

sciences LTD (UK). From Sigma-Aldrich (Germany) sodium hydroxide (NaOH) was

bought.

In acetic acid (0.5 M, 2.5 ml) Chitosan

(0.2g) was dissolved and stirred for 1 hour and 30 min at room temperature.

Powdered dexamethasone (3.5 mg) was added and stirred for further 30 min at

room temperature. This solution was placed at 4°C for 30 minutes to cool

it down. After this, NaHCO3 solution (0.48 M, 2 ml) was added drop

wise. In the meanwhile, pH change was monitored and finally maintained at 7.

Constant stirring was done to remove effervescence. Once required pH was

achieved, solution was placed inside oven at 37°C. Formation of gel started

after 3-5 minutes and it happened from the surface first. It took 2 hour for complete

conversion of liquid into hydrogel.

Test tube invert method was used to analyze

sol-to-gel transition. In this method, 0.5 ml polymer solution of given

concentration was taken in 3 different vials. The vials containing polymer

solution were placed at 4°C for 30 min – 1 hour. After this, each vial was

immersed in separate water bath having different temperatures i.e. 10°, 25° and

37°, for 10 min. After 10 mins, each vial was taken out and inverted to

180°. If no visible flow was observed

within 30s of inversion, sample was considered as “gel”.

The pH of sample before and after gelation

was calculated by calibrated pH meter (Eutech instrument pc 150). Neutral pH is

the indication of completion of reaction between acid and base which is

required for conversion of sol-to-gel. Also, acidic or basic gel implant can

cause irritation to the eye and can permanently damage the tissue. Therefore,

it is important to measure the pH of the gel.

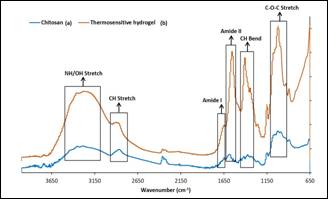

Structural characterization of prepared

thermosensitive hydrogels was carried out by Fourier transfer infrared (FTIR)

spectroscopy, coupled with smart ATR accessory. Thermo-Nicolet 6700P FTIR

Spectrometer (USA) was used and the average number of scans were 256 at the

resolution of 8 cm-1. Spectra that were recorded ranged in

wavelength of 4000-650cm1.

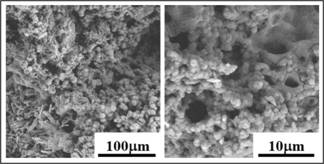

Scanning electron microscope (Tescan, Vega

LMU) at 10 kV under low vacuum mode at 10 Pa was employed for the assessment of

pore size and compact structure of synthesized hydrogel. At different

magnifications images were obtained. Image processing software (Image J) was

used to calculate the diameter of pore by selecting 30 pores randomly.

For every

sample composition (n=3) degradation tests were performed gravimetrically. Two

weights were taken to achieve this purpose. Before immersing them into

solutions, initial dry weight (![]() ) of hydrogels was taken. Then

the samples were kept in phosphate buffered saline (PBS), lysozyme solution

(1mg/ml) in PBS at 37oC for different time points (day 1-day 28).

The samples were taken out at each time point, dried at 37oC for 24

H and subsequently weighed (

) of hydrogels was taken. Then

the samples were kept in phosphate buffered saline (PBS), lysozyme solution

(1mg/ml) in PBS at 37oC for different time points (day 1-day 28).

The samples were taken out at each time point, dried at 37oC for 24

H and subsequently weighed (![]() ). The dried weight (without

water content) remaining ratios were determined as following:

). The dried weight (without

water content) remaining ratios were determined as following:

![]()

Drug

release test was carried out in PBS. For this purpose, powdered dexamethasone

was added in stirring solution of chitosan and sodium bicarbonate wherein drug

content was 0.7 mg/ml. After adding drug, resultant mixture was placed in oven

at 37°C to form gel. Hydrogel was cut into triplicates of equal weight (10 mg)

and dipped into 5 ml PBS solution. At different time intervals (after 3 h,

after 16 h, after 24 h and after 48 h) PBS solution in vials was replaced with

the fresh one. Collected PBS solutions were analyzed under UV/Visible

spectrophotometer (Perkin Elmer). Amount of drug release was determined by

following straight line equation:

![]()

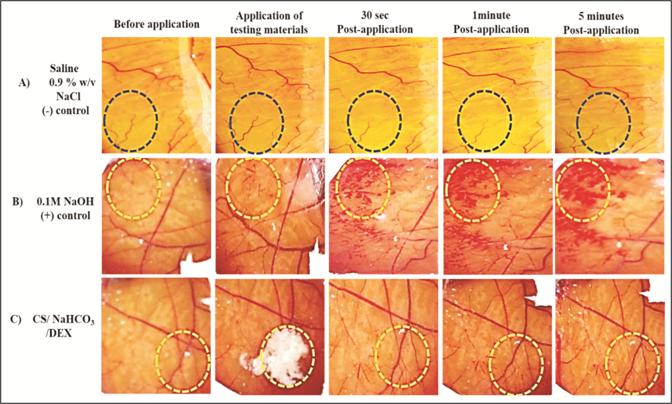

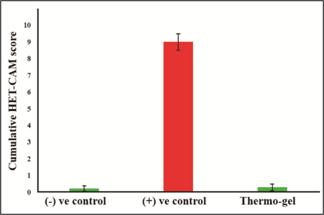

HET-CAM (Hen’s egg test –

chorioallantoic membrane) assay, most robust and successful assay, was used to

evaluate irritation properties of chemicals and consumer products that might come

in contact with human eyes. The assay covers a broad spectrum of chemicals with

whole range of degrees of irritation and physical appearances of different

substances. To evaluate the ocular tolerance of the developed thermosensitive

hydrogel, HET-CAM test was performed with small modifications.

Briefly, freshly

fertilized hen’s eggs were bought from Big Bird Group (Lahore, Pakistan). They

were put in an incubator at 37.8 ± 0.5°C and 55% humidity for nine days. At day 10, the egg shell

was opened, and white egg membrane was removed carefully without injuring any

underlying blood vessels. Subsequently, the surface of the CAM was exposed to

0.1g of the test substance, 0.1 M sodium hydroxide (NaOH) solution (positive

control), and a 0.9% NaCl w/v saline solution (negative control). The chorioallantoic membrane and

its clearly delineated vascular system was further assessed subjectively in

terms of hyperemia, hemorrhage

or coagulation. Changes were examined using a light microscope (Mitotic, China)

before exposure and at different time points post-application for 5 min.

Scoring of each test substance was designated by using a classification

system previously described by Luepke

and Kemper (1986): Non

irritation: up to 0.9; slight

irritant: 1-4.9; moderate irritant:

5-8.9; severe irritant: 9 and

above. Moreover, images were obtained before application and for 30 s, 2 min,

and 5 min after exposure.

RESULTS

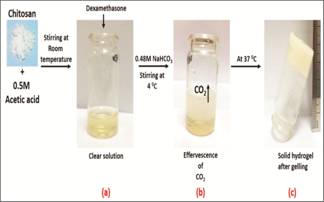

In the preparation

of Thermosensitive Hydrogel of Chitosan and loading with Dexamethasone, it was

shown that neutralization occurred which resulted in the formation of

physical junctions (hydrogen bonding) between polymeric chains of chitosan. In chemical structure analysis by Fourier

Transform Infrared Spectroscopy it was shown that

Fig. 1: Step by step illustration of

synthesis of thermosensitive hydrogel.

Fig. 2: FTIR results of pure

chitosan (a) and thermosensitive hydrogel (b).

only temperature changed

the physical appearance of polymer which was not significant.

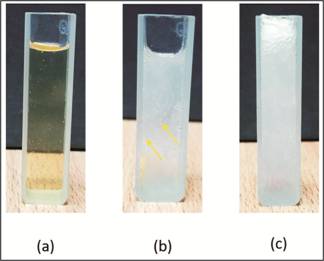

Fig. 3: Sequence of pictures illustrating

physical changes occurred at 37°C. (a) Clear solution mixture before gelation.

(b) Gelation started at 37°C. (c) Gelation completed at 37°C. Yellow arrows are

indicating effervescence of CO2.

Fig. 4: Scanning electron

micrographs of synthesized hydrogel (magnification bars are given with each

image).

Characterization

of Sol-to-Gel transition temperature by Test-Tube invert method showed that no CO2 was released at 4°C hence no gelation occurred.

At 25°C, no gelation was observed within 10 minutes. But after immersing vial

for 2 h, gelation started at very slow rate. Best results were obtained at

37°C. Before gelation the pH was 4.9 and after gelation it was 7.14.

In-vitro drug

release results showed that hydrogel can stay in sub-tenon region of eye

over a month and release drug. Based on these results, we are proposing that

our synthesized biomaterial will be the first thermosensitive chitosan based

hydrogel which will support sustained release of dexamethasone in sub-tenon

region of the eye.

To assess degradation potential of synthesized biomaterial,

in vitro degradation test were performed.

Fig. 5: In vitro accumulative

release of dexamethasone from chitosan hydrogel.

Fig. 6: In vitro degradation in

PBS and Lysozyme.

We managed to mimic the physiological

environment by selecting two media for degradation; PBS and lysozyme. From the

results, it was concluded that synthesized materials were degradable. PBS and

lysozyme, both caused degradation to synthesized hydrogels. Statistical

analysis revealed significant difference (p = 0.0005) between the degradation

values of day 7 and 28.

In ocular irritancy test by HET-CAM

which is a semi qualitative test to asses the irritation potential of a testing

material. From figure 8, it was concluded that synthesized thermosensitive

hydrogel was not irritant.

DISCUSSION

In the

preparation of Thermosensitive Hydrogel of Chitosan and loading with

Dexamethasone, the gelling mechanism of solution mixture of chitosan at 37°C involves neutralization of chitosan solution in the presence

of NaHCO3 (Figure 1). When chitosan is dissolved in 0.5M acetic acid

solution, protonation of amino groups of chitosan takes place. At this point

the pH of solution is 4.9. As 0.48M of NaHCO3 solution is added into

the 0.5M of chitosan solution, CO2 evolves. By experimentation, it

is concluded that this neutralization reaction occurs only at or above 37°C19.

In

chemical structure analysis by Fourier

Transform Infrared Spectroscopy, FTIR spectra are obtained for pure powdered

chitosan and synthesized thermosensitive hydrogel. Broad peak between 3200-3500

cm-1 appears due to NH/OH stretching vibrations. The absorptions

present in the range of 2919-2910 cm-1 are assigned to CH stretching

vibrations and peaks for CH bending vibration were present around 1400 cm-1,. The absorptions around 1650 and 1585 cm-1 are

attributed to amide I (-C = O stretch) and amide II (-C-N stretch and -C-N-H

bending vibrations), respectively20. It is found that C-O-C deformation band appears around 1097cm1

Characterization of Sol-to-Gel transition temperature by Test tube invert

method is used to analyze the temperature required for sol-to-gel transition.

For this purpose, 5 mL of fresh chitosan/NaHCO3 mixture having

dispersed dexamethasone is added into vial. This vial is immersed in water bath

for 10 minutes at three different temperatures: 4°C, 25°C and 37°C. Gelation

time is observed by tilting vial at an angle of 90° for 1 min till no flow.

From

results it is observed that no CO2 is released at 4°C hence no

gelation occurs. At 25°C, no gelation is observed within 10 minutes. But after

immersing